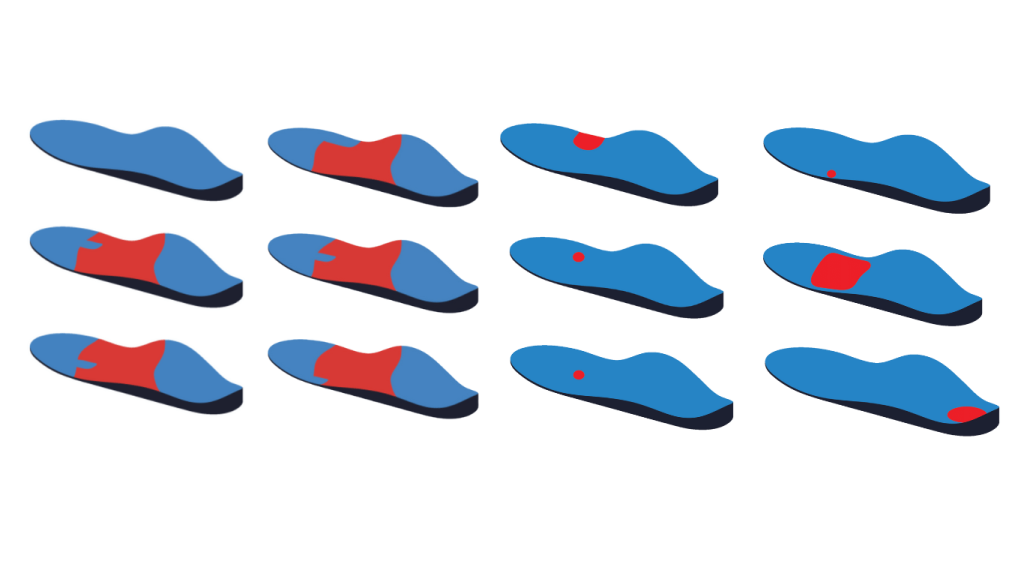

Base Block

Our EVA is routinely tested to ensure a consistent density and an optimal compression set of 5%.

We direct CNC mill our block. No destructive heating occurs at any point.

Our EVA has extremely low filler % resulting in a longer lasting, more consistent product. We also manufacture PA12 nylon powder laser printed rigid devices.

Mid Layers

OBD offers porons of various thickness to increase device cushioning. This helps with various shoe fits.

We can also apply an optional polyurethane mid layer for clinicians that prefer easily removable top covers.

Top Covers

OBD offers premium top covers with varying colours, thicknesses and densities in: EVA, neoprene, microfibre, leather, vinyl and cashmere. We employ strict quality assurance measures to produce consistently great final products